How Prefab Cables Save on Time and Manpower

We live in world now where there is increased competition on quality construction manpower. This problem is exacerbated due to COVID-19, which has brought upon tightened travel restrictions and increased on-site safe distancing measures for health and safety reasons.

As such, even post COVID-19, we believe there is a growing need for solutions that are able to help reduce certain manual or repetitive tasks at construction sites so that the manpower is freed to take on other more productive roles instead.

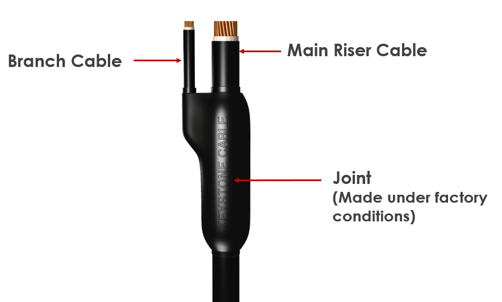

At Keystone, we manufacture a prefabricated branch cable system, KEYFAB™, where the joints connecting the main cable to branch cables have been pre-moulded under factory conditions. Such prefabricated branch cable systems are applicable for use in high-rise buildings as main risers, as well as for tunnel lighting.

With most of the work carried out in factory rather than on-site, prefabricated branch cable systems like KEYFAB™ deliver the following advantages:

Reduction in Labour Time and Cost

As the tap off (splicing and jointing) is already done at the factory, time savings on this task have been greater than 50% based on actual customer feedback*.

Not only is less manpower required during this process, it also eliminates the need for skilled labour to do the actual tap off.

*Field feedback from actual KEYFAB™ users

Reduction in Material Cost

KEYFAB™ cables are designed to fit your specific length requirements and excess cable is trimmed to prevent material wastage. They can be fixed to the wall with cleats or brackets.

Enhanced Reliability

As the fabrication process is done in a stringent quality-controlled environment, certified by a third party, the joint is more reliable than if it were done on-site which could be prone to human error.

Completely airtight and waterproof, KEYFAB™ cables also prevent problems associated with moisture ingress during and post construction phase.

Testing & Standards

To ensure that Keystone Cable’s KEYFAB™ delivers maximum performance, we carry out rigorous testing under factory conditions individually for the cables and joints and then as a whole system, to verify compatibility.

KEYFAB™ tests include:

• Type Test

• Heat Cycling Test

• AC Voltage Withstanding Test

• Insulation Resistance Test

• Connector Resistance Test

• KEYFAB™ Fire Resistant Cables series have also undergone fire (BS 6387, SS 299, IEC 60331), fire with water (BS 6387, SS 299) and fire with mechanical shock tests (BS 6387, SS 299) to ensure the cables maintain circuit integrity under fire conditions.

Keystone Cable’s KEYFAB™ has been installed in hotels, residential and commercial projects. The following pictures are based on actual KEYFAB™ installations.

For a free product webinar on the details, register your interest here!