Conductor Resistance: A basic but important test for your cables

The conductor resistance (CR) test is basic, but one of the most important tests in quality testing of cables. It can verify whether the amount or quality of conductor material in a cable is sufficient.

The conductor resistance (CR) test is basic, but one of the most important tests in quality testing of cables. It can verify whether the amount or quality of conductor material in a cable is sufficient.

The CR test is done on either a complete length of cable or on a cable sample of at least 1m in length in accordance with IEC 60228. The test measures the DC resistance of the copper or aluminium conductor, which indicates how easily current can flow through the conductor; the higher the resistance, the less current flow. When the resistance is too high, the heat generated may cause premature insulation failure, resulting in a fire or short circuit.

CR is influenced by the conductor dimensions, construction, temperature, and resistivity. Out of these factors, it is worth highlighting that because of the sensitivity of the reading to temperature, it is important to keep the sample in the test area for sufficient time to ensure that the conductor temperature has stabilized, which allows for an accurate test. The measured resistance is then converted to an equivalent resistance at standard temperature -- 20°C according to IEC 60228 -- and length.

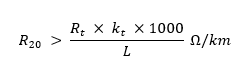

To ensure that the conductor resistance meets the standard, the observed resistance Rt is compared against the maximum conductor resistance at 20°C (R20) where: Rt = Observed Resistance

Rt = Observed Resistance

kt = Temperature Correction Factor (Table 1)

L = Length of the specimen in m

R20 = Maximum Standard Resistance at 20°C (Table 2)

If you come across a high conductor resistance reading (> R20), here are possible calculation adjustment factors to first consider before exploring actual conductor issues:

1. Incorrect conductor temperature (a higher conductor temperature >20°C would result in a higher observed resistance, Rt)

2. Incorrect length of cable (a longer length of cable would result in a higher observed resistance, Rt)

Otherwise, there may be a case of:

3. Insufficient conductor purity (e.g. where the copper is less than 99.9% pure)

4. Insufficient conductor quantity (e.g. thinner or shortage of strands of wires resulting in a smaller conductor cross-sectional area)

At Keystone Cable, the CR test is a routine test we conduct on every finished cable to ensure that the results comply with international specifications.