Understanding mechanical testing for cable longevity

What is the purpose of mechanical testing?

Power cables, typically installed underground, in ducts, or on overhead structures, are often subject to mechanical stresses such as tension, compression, bending, and twisting. Hence it is important that cables are put through stringent tests to ensure they can withstand the mechanical stresses that they will be subjected to during installation, operation, and maintenance.

One of the categories we test for in mechanical testing, is the Tensile Elongation test, which affirm that cables manufactured are equipped with mechanical capabilities including flexibility and load-bearing capabilities. By subjecting the cable’s insulation and sheath to tensile elongation test, we can compare it against predetermined minimum elongation and tensile strength based on standards to identify potential weaknesses in the cable’s design or materials to optimise performance. This is fundamental to providing our customers with reliable cables.

As cables are meant to operate over a lifespan of 20 to 30 years under normal use conditions, how can we ensure that cables continue to retain mechanical integrity even after long term use?

The Tensile Elongation Test

We subject our cables to Tensile Elongation to determine whether they can retain tensile strength and elongation after being exposed to a tension load. This assessment determines the cable’s ability to maintain mechanical integrity at ambient temperatures, and is one of the key mechanical tests our cables need to withstand.

In this test, a tubular or dumb-bell control sample is prepared and placed in an electromechanical or universal testing machine with 2 clamps and pulled from each end until its breaking point. The test measures the amount of force (N) applied and elongation when the sample breaks (∆L).

|

Tensile strength - Amount of force (N): Strength needed to pull the material of the cable until it breaks. The maximum strength it can tolerate |

Elongation(∆L): The length that the material of the cable can be stretched until it breaks |

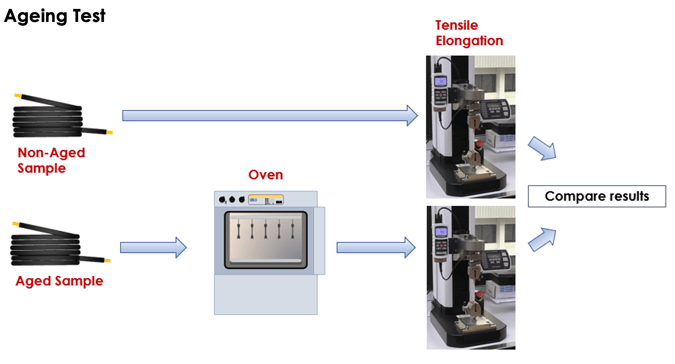

Subsequently, the control sample is used as a baseline and compared with an aged sample placed in the oven and thereafter subjected to the Tensile Elongation test. Read on to find out more about how we age cable samples.

Ageing Conditions Samples

To ensure that the cables can maintain mechanical integrity over a 20–30-year lifespan, we subject the materials to accelerated ageing conditions to verify that prolonged use does not negatively affect the cable. It is important to conduct comparison tests with non-aged samples after an accelerated ageing process.

To perform the ageing test, the cable is placed in an oven to accelerate the ageing process, simulating decades of usage. This is in line with IEC 60811- 401:2012 standards, which typically applies to crosslinked and thermoplastic compounds used for insulating and sheathing materials in the ageing oven process. The samples placed in the oven are called aged samples.

The Importance of Testing

A successful outcome provides assurance that the cables will have a long and reliable service life, which is critical for the safe, efficient operation of electrical power systems, and minimise waste as a result of cable longevity. If a cable is unable to withstand mechanical testing, it can lead to unsafe situations at project sites.

At Keystone Cable, mechanical testing is a standard component of our cable testing regimen. This is our assurance to you that our cables are reliable and adhere to international specifications.

For more information, please may reach out to our sales team.